Designer Furniture Part 1: Tips on Choosing Pieces with Quality Construction and Materials

Why do furniture pieces run the gamut when it comes to pricing? It depends on any number of things, but, above all, construction methods and quality materials are what differentiates high-end designer furniture from mid-market furniture. Interested in learning more? Read on. In part one of two here, I’ll touch on the topics of construction, frame, and joinery.

(If that holds your attention, I hope you’ll read part two where I talk about springs, cushions, and fabrics for high-quality upholstered furniture.)

Furniture Construction: Mass Production, Handmade, and Benchmade

Mass production

Lower-cost furniture is typically factory made, which means it is mass-produced by a design print often on an assembly line. This type of furniture is most common. It is not known for its longevity, but rather for its affordability.

Machines do the heavy lifting of cutting and gluing the parts together, often using engineered materials like MDF (medium-density fiberboard). MDF is comprised of broken-down wood fibers, resin and wax, which is then formed into panels. Veneers ─ thin pieces of fine wood like oak or walnut ─ are typically applied to the top of the MDF to enhance the appearance of the furniture. Various chemicals are involved in this entire process as you might have guessed.

Production furniture is an option for renters who haven’t moved into their dream homes yet or first-time homeowners starting out on a smaller budget. Many mass-produced furniture lines are attractive, are available in multiple sizes, and are designed by well-known professionals.

Handmade

Handmade pieces are the environmentally responsible choice, in addition to being the most visually appealing. No two pieces are alike because no two wood grains are alike. Each one-of-a-kind piece has character and charm all its own. They require a team of people to complete with each person using their advanced skills throughout the process to create beautiful high-end furniture.

Handmade furniture is generally crafted using manual labor and traditional techniques. Craftspeople use a combination of power tools and hand tools to precisely hand-cut wood frames. Most handmade pieces are custom and use high-quality, natural materials (think kiln-dried solid hardwoods, top-grain leather, and tightly woven fabrics). This is a great option for homeowners investing in their dream home who value quality, durability, and customization. These pieces will stand the test of time – even a lifetime – and can be reupholstered to look completely fresh whenever desired.

Every frame is cut and assembled by hand at Sherrill Furniture in Hickory, NC

Benchmade

“Benchmade” furniture takes handmade to the next level and usually means that it was crafted by one person from start to finish, like art. Benchmade furniture is built to order and is only carried out by the most exceptionally skilled and experienced craftspeople with extreme care and time. Benchmade can also refer to a woodworker and an upholsterer who team up to build a custom piece with precision and detailing unique to that piece.

Wood detailing is carved by hand, stains and finishes are applied by hand, and upholstery is hand-cut to perfection. Benchmade furniture is ideal for those who are in their “forever home” and want stunning heirloom pieces they can pass on to future generations.

Example of benchmade furniture, courtesy of

Western Heritage Furniture in Bradford, IL.

Frame

The structure of your furniture is key – what material is inside of it? The best furniture is constructed from solid kiln-dried hardwood frames. Oak, alder, birch, acacia, ash, walnut, and maple are ideal hardwoods for high-end furniture. Multiple layers in the frame result in resilient – and virtually indestructible – furniture.

North Carolina is home to many of America’s top furniture companies specializing in handmade and benchmade furniture. Their teams dry wood in a kiln (a big oven) to remove moisture before it’s crafted for furniture. This step is critical because it prevents warping and cracking, which results in extremely durable furniture. The kilning process also kills larvae, eggs, bugs and mold in hardwoods and makes the wood resistant to fungal decay.

All pieces are handmade or benchmade with outstanding craftsmanship at Lee Industries in Conover, NC.

Joinery

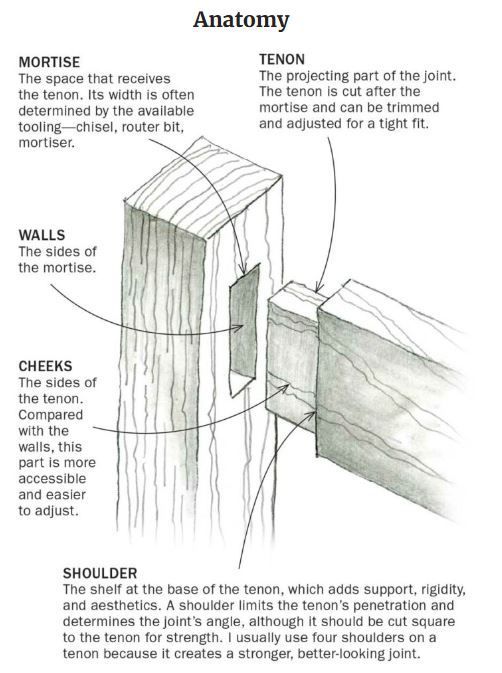

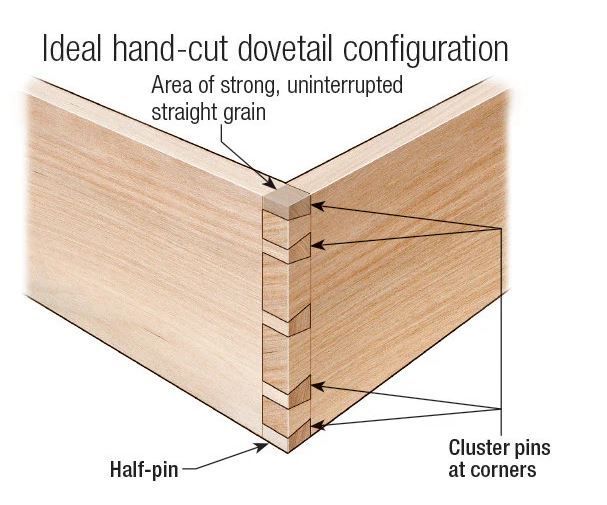

After carpenters carefully cut and carve furniture elements, they must be joined together (joinery). The stronger the woodworking joints, the better and long-lasting the piece of furniture. Widely considered the most popular, strongest, most reliable, and aesthetically pleasing joinery methods are mortise and tenon and dovetailing.

Mortise and Tenon Joint

The mortise and tenon technique has been around since 4,900 B.C.! A mortise (hole) is carved into one piece of wood, and a tenon (peg) fits tightly into it; the two are glued together. You will find this feature in heirloom-quality handmade and benchmade furniture.

Dovetailing

Similar to mortise and tenon, dovetail joints date back to Ancient Egypt. It’s a joinery technique that uses pins and tails that interlock together, followed by gluing. You can see dovetailing most often used on well-constructed drawers, and they are nearly impossible to pull apart after gluing.

Now that you know some of the basics to look for, please

read on to my next post about springs (suspension systems), cushions, and fabrics in upholstered furniture.

Edit Interiors | All Rights Reserved | Website designed by Artisan Launchpad